A hoistway or shaftway is an enclosed area that is used to house the elevator as it travels between levels in your home. This area will run vertically from the lowest floor to the top floor. The hoistway should always be built to meet local codes and the elevator manufacturer’s specifications. In some jurisdictions, a hoistway must also be fire-rated. Hoistways can also be constructed on the exterior of a home or built on the side or rear of a house, depending on local building codes and community guidelines.

Hoistway plans

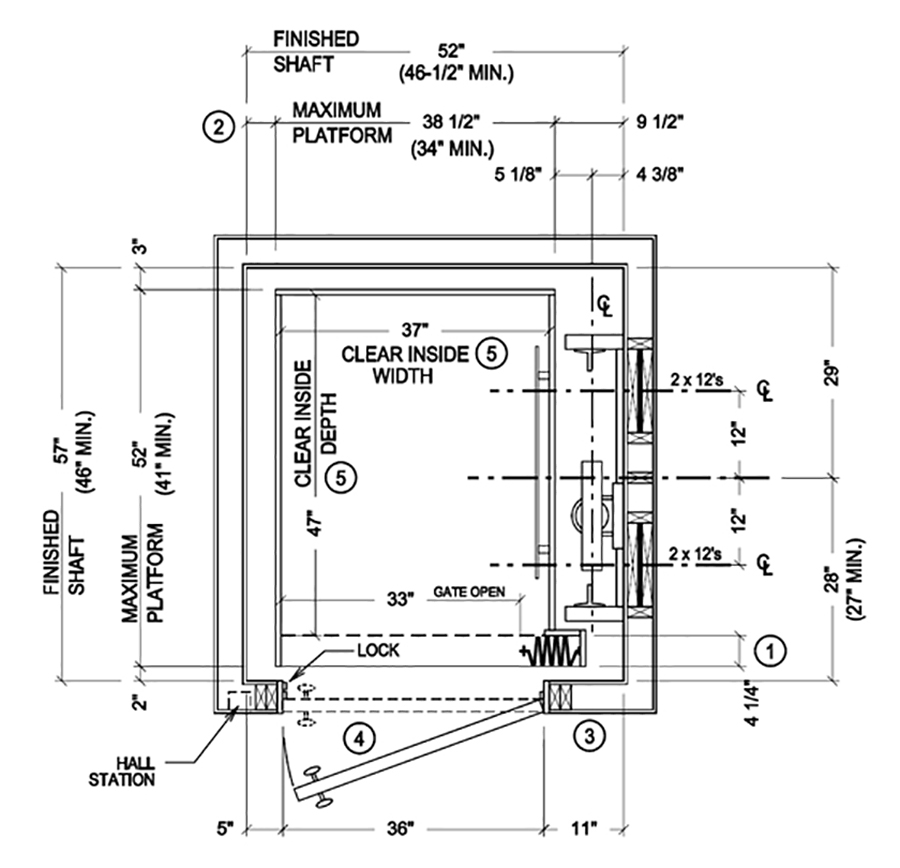

When constructing a hoistway, you’ll always need to work off an approved and final set of plans provided by your local elevator contractor. It’s important to remember a hoistway is a critical element of any elevator installation and must be built perfectly square and plumb with the proper load specifications. Hoistway dimensions are exact and not something that can easily be adjusted or changed later. Shown here is a typical elevator hoistway plan fitting a standard cab size.

Load walls

Hoistways will typically have special supports or bracing built into the load wall to attach the elevator as shown here. These supports will run vertically from the lowest floor to the ceiling on the highest floor and will be specified by the manufacturer for precise location.

Planning ahead

While in the framing stage of hoistway construction, leave time for your elevator contractor to prewire the walls for the landing controls and door interlocks. This is also a perfect time to install automatic lighting at each landing by the hoistway entrance doors.

Elevator pit

An elevator pit is a recess in the lowest landing floor designed to give the elevator car frame room to park while keeping the cab entrance and threshold level with the landing. The elevator pit area will be the same width and length as the hoistway but can range in depth from 6″ to 12″, depending on the elevator type. The pit is the base of the elevator shaft, and for hydraulic models, this area must also be reinforced and engineered to carry the loads placed on the pit floor by an elevator.

The 12″ deep pit shown here is for a hydraulic home elevator, the pit floor is reinforced with steel rebar and extra-thick concrete. In some areas, a drain in the center of the pit may also be required. It’s important to note elevator equipment should not come in contact with water. If you have a property with groundwater issues, you’ll want to also take extra precautions to have the pit sealed and waterproofed before installation of the elevator. There are several companies that specialize in pit waterproofing, and it’s much easier to do before an elevator is in place.

The pit is an integral part of a hoistway that should be cleaned and checked when annual maintenance is done by your local elevator company. It’s extremely important for safety that only trained and experienced elevator technicians enter this area. If keys or a cell phone are dropped into the pit, you’ll need to contact your service company to retrieve these items.

The underside of an elevator car frame and floor system in a hoistway for homes. The metal undercarriage and the mechanical components of an elevator will rest in the pit while parked at the lowest landing.

The elevator threshold is level with the landing while parked on the lowest floor. The typical horizontal clearance between the elevator threshold and landing is 1/2″ to 3/4″ max.

There are many elements to a hoistway that must be carefully monitored to ensure the proper installation of an elevator. You’ll want to make sure it’s done correctly, and it’s always a good idea to have your elevator contractor perform site visits to check at the various stages of construction.