Traditional winding drum elevators and how they work. The classic winding drum elevator would typically be used where a machine-room, pit, and full hoistway space are available. While there are many alternatives available to this type of elevator, some prefer this style over hydraulic or machine room-less chain drive systems.

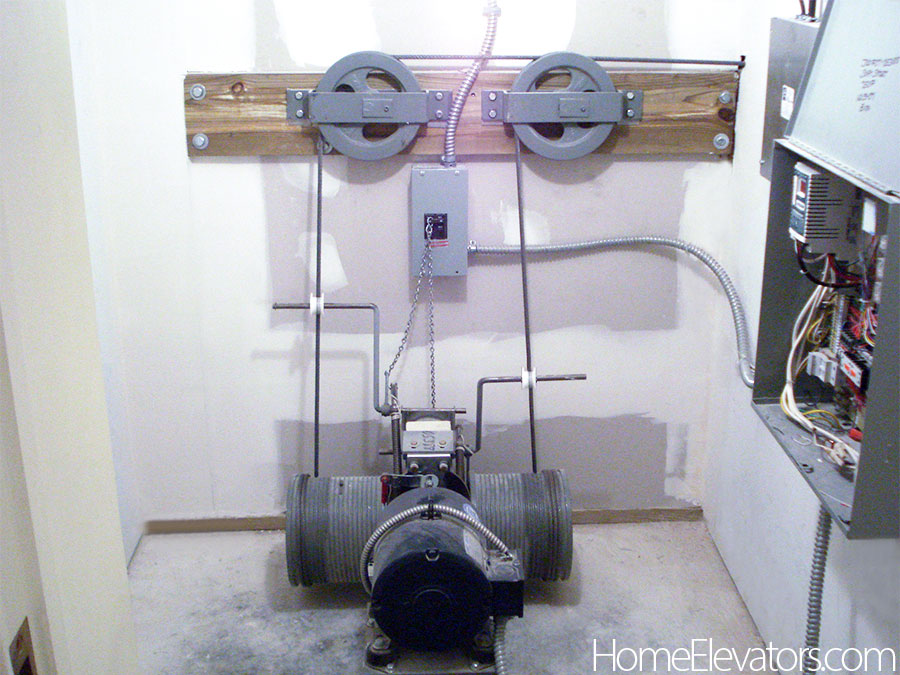

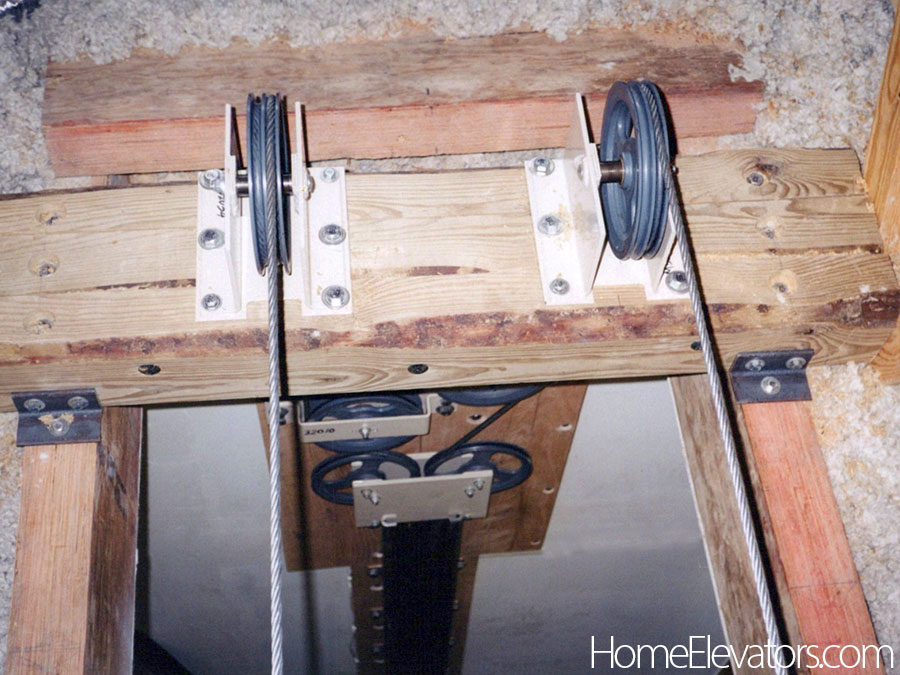

Winding drum cable elevators operate with an electric motor to wind two cables or wire ropes directly onto steel drums that raise and lower the elevator. This type of elevator does not use counterweights similar to traction elevators.

Traditional style models will require a hoistway, pit, and machine room. More modern models like the Vuelift will have their own enclosure and space to house the control and drive equipment. Winding drum elevators will typically have a 500-750lb. Capacity and can serve anywhere from 4-5 floors, depending on the manufacturer. The ride quality tends to be standard, with a slight bounce on the initial movement of the cab, and varies on the different models.

A pro to this type of system is the drive or motor assembly can be placed in many different locations when using a machine room. The wire ropes can be routed to the drive or drums using sheaves. This is helpful in the design stage of placing the machine room and also allows for more cab configurations if needed.