LULA elevators are specially designed elevators engineered for limited use limited applications used mainly in commercial buildings. A LULA elevator is primarily used for installation in existing buildings where it’s not feasible to install a full-size passenger elevator and where a standard pit or overhead clearances are not available. LULA elevators are typically installed in churches, schools, small commercial buildings, lodges, retirement homes, and office spaces.

Standard LULA Specifications

LULA elevators are permitted to travel up to 25 feet, have a standard capacity of 1400 lbs., and have a rated speed of 30 fpm. Additional travel may be permitted with a variance. However, a LULA elevator is generally limited by speed, travel, and capacity to comply with ASME A17.1 Section 5.2. Local code authority may have additional requirements

Cost of a LULA Elevator

LULA elevators can cost the same as passenger elevators and, in some cases, can be even more expensive. The average price of a LULA elevator is $60,000 -$70,000 for a standard 2-stop installation.

LULA Installation

LULA elevators are considered to have long lead times for manufacturing and production. You’ll want to plan several months for the full process to take place. The production of the elevator will usually take 10-12 weeks, after all approvals. The approval process can take several weeks in its self with submitting shop drawings back and forth to the architectural team for review.

After the elevator is delivered to the site the actual installation can take an addition 7-10 days on average. Installation of a LULA elevator is a coordinated process between the elevator company, the mason, the electrician, and the general contractor. For example, the masonry shaft can be built on three sides however, the entrance must be built after the elevator is installed in the hoistway and the door frames are set in perfect alignment with the opening of the elevator. After installation the elevator will still need to be inspected and approved.

LULA Machine Rooms

The machine room for a LULA elevator will have similar requirements to a regular passenger elevator however, the space needed to fit the control system and drive is usually less.

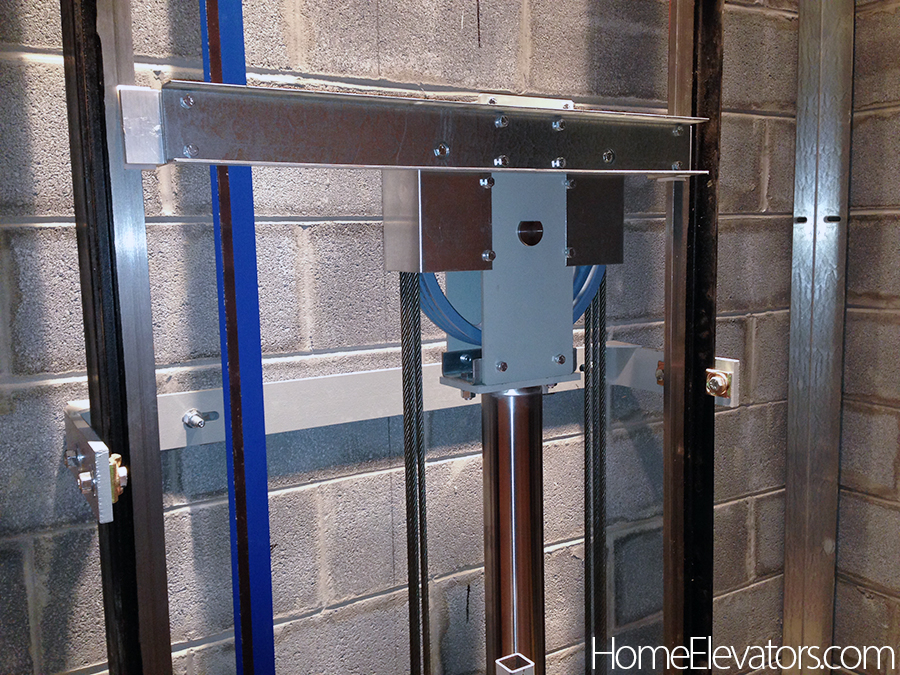

Typical LULA Pit

One of the many benefits of LULA elevators is the reduced pit depth requirement. The pit shown here is a typical 14″ deep pit. While the required pit depth is less for a LULA you will still need the standard pit equipment with proper lighting, pit switch, GFCI outlet and in most locations a sump pump fitted with an oil filtration system. The reduced pit depth is made possible by a shallow pit device that is retractable and attached to the elevator frame.

LULA Elevator Manufacturers

The manufacturers who specialize in the design and production of LULA elevators focus on compliance with accessibility regulations, safety standards, and space efficiency. They play a crucial role in enhancing mobility in small-scale commercial buildings, offering a blend of functionality and convenience while addressing the specific needs of buildings that require a smaller, yet fully functional elevator system. A few of these manufactures include:

- Custom Elevator Manufacturing (shown above) Model IL-1 Plan

- Symmetry Elevating Solutions

- American Crescent Elevator

- Garaventa Lift – Elvoron

LULA Elevator video

Quick overview of a LULA elevator with 2-stops and automatic side sliding doors. Cab doors, trim, and cab operating panel are stainless steel. The cab wall color is wild cherry. The interior cab size is 3′-6″ wide x 5′ long. The finished cab height is 6′-8″. The hoistway landing doors have a black baked enamel finish. Total travel is 12′-10″, pit depth is 14″ deep, and clear overhead at the top landing is 9′-6″.